We had some rain on and off all day. Next we drove to a town about 30 min away called Harsewinkel where there is a HUGE factory that makes farm equipment and columbines.

The tour of the facility was long and detailed. They said 20,000 people/year tour the factory. We walked about 4km. Sadly, this is a vacation period for all of the 12,000 workers, so all of the assembly lines were empty of employees at work. We saw an empty HUGE factory.

It was interesting. Every columbine has more than 40,000 parts. The factory covered acres and acres of land and was 3 stories high in most places. They move parts and pieces by robot on tracks up above the ground floor. It was a master-minded production line. Employees use bicycles to get from one part of the factory to another. There are bike stops and bike lanes. They make about 15 huge columbines each day, some cost up to $1 million. All are pre-ordered and pre-paid. There are 500 machines in the back lot waiting to be delivered.

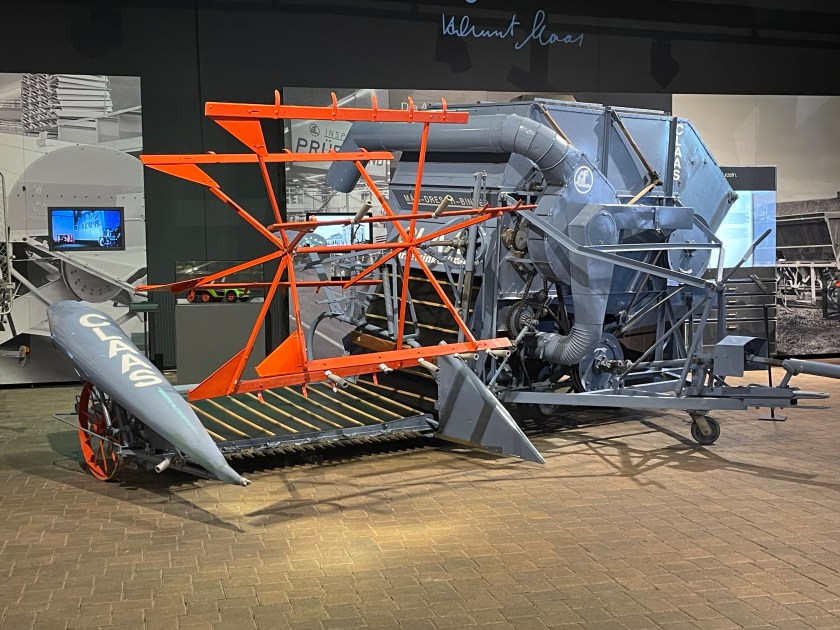

Here’s the showroom. We weren’t allowed to take photos in the factory.

We watched a film about the company before touring the manufacturing plant.

This gives you an idea of the size of this place:

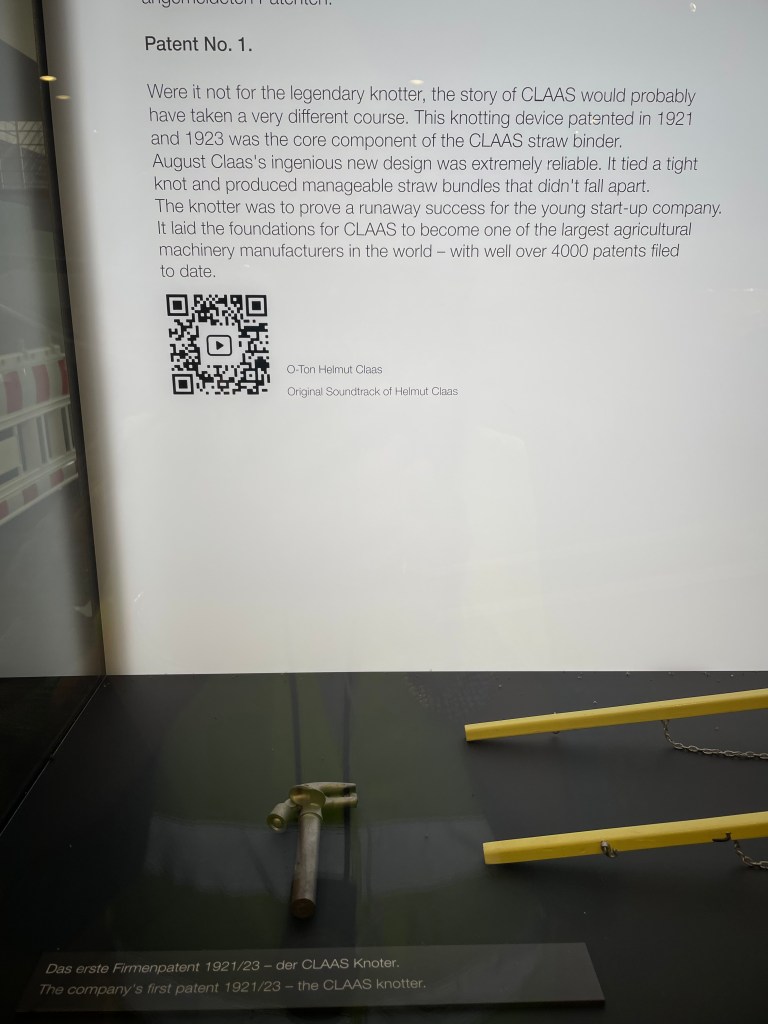

This little knotting device was the beginning of all of this:

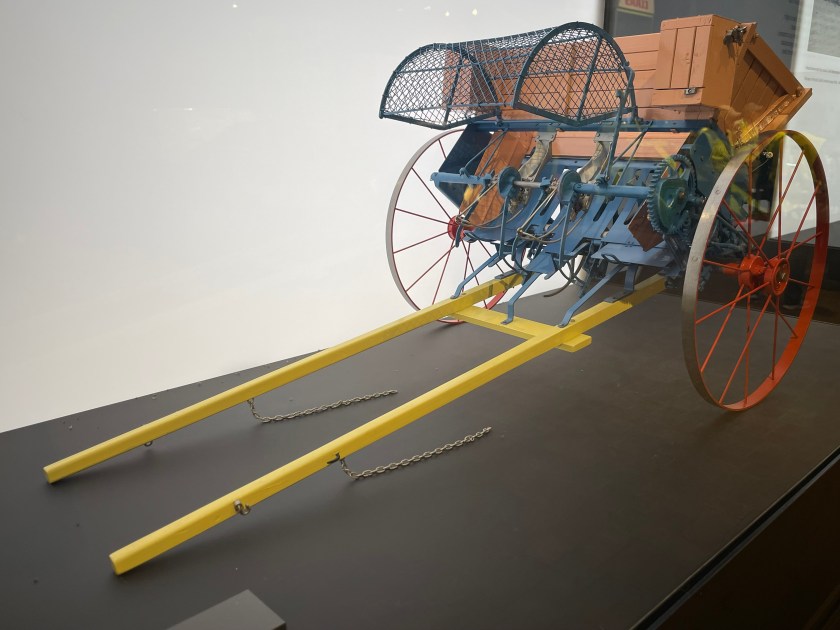

Early harvesters:

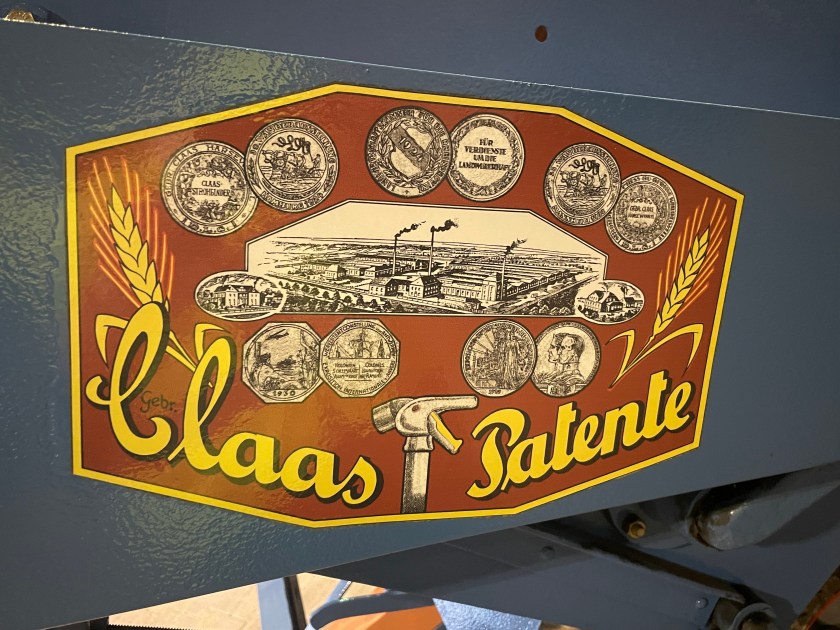

Here’s some info about what we learned here:

CLAAS is an agricultural machinery manufacturer based in Harsewinkel, Germany, in the federal state of North Rhine Westphalia. Founded in 1913 by August Claas, CLAAS is a family business and one of the market and technology leaders in harvesting technology. It is the European market leader in combine harvesters and considered as world market leader in self-propelled forage harvesters. The product range also includes tractors, balers, mowers, rakes, tedders, silage trailers, wheel loaders, telehandlers and other harvesting equipment as well as farming information technology. CLAAS employs around 11,500 employees worldwide and reported a turnover of roughly 3.9 billion euros in the 2019 financial year. About 78.5% of sales are generated outside of Germany.

History

Early days

The beginnings of the company go back to 1887, when Franz Claas founded a company in Clarholz for the production of milk centrifuges. From about 1900 onwards, he also manufactured other agricultural machinery there, such as straw binders and cutters for mowing machines.

The official foundation of the company took place in 1913, when the son of Franz Claas, August Claas, informed the responsible office in Herzebrock that he was manufacturing straw binders with two locksmiths and one unskilled worker. In 1914 his brothers Franz jun. and Bernhard Claas also joined the company. The company was then continued under the name “Gebr. Claas.” The fourth brother, Theo, officially joined the company as a partner in 1940.

Growth period

After their return from the First World War, the Claas brothers and sisters moved their company to Harsewinkel in 1919, where they bought a disused hard stone factory and continued production. The export of Claas products now also began from Harsewinkel, initially to Holland, France and Belgium.

In 1930, the development of the first CLAAS combine harvester began, initially as machines using the fore-cut principle. The first CLAAS straw baler was produced in 1931. In 1936, the company launched the first combine harvester designed specifically for European harvesting conditions, the combine harvester (ger. Mäh-Dresch-Binder – MDB). This was then mass-produced from 1937. Until the production was stopped due to the war in 1943, approx. 1400 machines were produced.

At the same time as the 1000th combine harvester was built in 1942, development of the CLAAS SUPER began. This came onto the market in 1946. By the end of production in 1978, more than 65,000 units had been produced by this combine harvester family.

In 1956 a new factory was established in Paderborn. This was now the third location besides the plant in Harsewinkel and the Christopherus-Hütte in Gütersloh-Blankenhagen, which was built in 1948. In 1961, the new CLAAS baler factory in Metz (France) was added, which has been operating under the name Usines Claas France S.A. since 1969.

Helmut Claas, the son of August Claas, became managing director for Engineering in 1962. By then CLAAS was already the No. 1 combine harvester manufacturer in Europe. 1969 saw the takeover of Josef Bautz AG in Saulgau with a factory for forage harvesting machinery. One year later, the Speiser company from Göppingen, which specialised in forage harvesting technology. The company continued to grow steadily and presented new products for forage harvesting such as mowers, tedders, windrowers, loader wagons and trailed forage harvesters.[4][5]

In 1978 Helmut Claas took over as chairman of the management board.

Products: Combine harvesters, Self-propelled forage harvesters, Tractors, Balers, Wheel loaders, Telehandlers, Forage harvesting machinery